Melissa Lesz began working at the Bakehouse in November 2005, right before our annual holiday rush. She’s currently the head of food safety at the Bakehouse but started as a pastry baker on the night shift. Within a year she was given the chance to serve as Pastry Supervisor. In 2015, after working her way through various leadership positions, she became the Pastry Manager and led the entire department for 6 years.

As someone formerly managed by her, I can say from experience that Melissa is a natural-born leader and an excellent, patient trainer. She really thrives in these roles, but, after almost half her life in the pastry kitchen, she was ready for a change. So she and Amy Emberling, Bakehouse Managing Partner, came up with a position that would benefit both her and the Bakehouse. She will be taking the reins from longtime Bakehouse food safety expert, Josh Pollock, after he goes into semi-retirement this month.

1. You’re the new head of Food Safety at the Bakehouse—congrats! Can you tell us about your new role and what it entails?

My official title is Project Manager. I wear a few different hats in this role.

My main responsibility is being a part of the Food Safety team. This means I work on and uphold our Food Safety Plan in a few different ways: conducting mock inspections, swabbing for environmental testing, and sending out samples of our food for allergen testing. All of these are verification steps to ensure the Food Safety work we are doing is working.

I also audit the paperwork and confirm it’s up to date; when we change or add a product, update a food safety practice, get a new piece of equipment, or a new chemical, the actual work systems and the paperwork need to be updated. Keeping the ingredient and nutritional labels accurate and up to date are also a part of this work. And most importantly, I train staff on our Safe Food Practices and our GMPs (Good Manufacturing Practices) to ensure we all know what needs to be done to keep our food safe.

I also continue to work in the Pastry department 2 days a week, training new staff and helping to develop new recipes and pastries, and I am part of the Pure Bakehouse team, our spontaneous baking project! When I’m excited about a new recipe, I get to make limited edition batches of goodies that are exclusive to our retail store. I didn’t want to get too far away from my passion for baking!

2. That sounds like a huge task and we thank you for taking it on with such enthusiasm! What sort of training or certification do you need to manage Food Safety in a commercial kitchen?

I completed a course with the National Sanitation Foundation (NSF) called Hazardous Analysis and Critical Control Point (HACCP) Training for Processors. This means I am now a Process Control Qualified Individual (PCQI).

I am originally a baker, with nearly 20 years of experience working in bakeries and kitchens. I’ve earned a certificate in Baking and Pastry from Schoolcraft College. I am ServSafe certified. And I have been training with my co-worker, Josh Pollock, who is also a PCQI, and who was responsible for the development of the Bakehouse’s original Food Safety Plan.

3. Beyond the Food Safety Plan that we’ve created at the Bakehouse, what organizations oversee food safety and set guidelines for food-producing businesses? How important is it that we follow them?

Because of our size, the Bakehouse is regulated by the Food and Drug Administration (FDA) and the Michigan Department of Agriculture and Rural Development (MDARD). The entire reason behind all of the food safety regulations is to ensure we are making safe food for our customers. So following these guidelines is crucial to continue to serve the quality and safe food that we are known for. We want to keep our customers healthy and enjoying our food!

4. I can imagine as the world becomes more developed and industry becomes more automated, things are continuously evolving in the world of food safety. Can you talk about your personal experience with it in all the years that you’ve been here? Has it changed much?

Wow! A ton! We have always followed the regulations, but as we continue to grow it means there is more to keep track of. A couple of the biggest pieces are the labeling and traceability and allergens. As more people develop allergies, we have to be aware of where they might be hiding (e.g. many chocolates contain soy lecithin). And soon the Big 8 (a government-regulated list of the top eight food allergens) will become the Big 9 with the addition of sesame.

5. What do you think has been the most challenging thing to stay on top of?

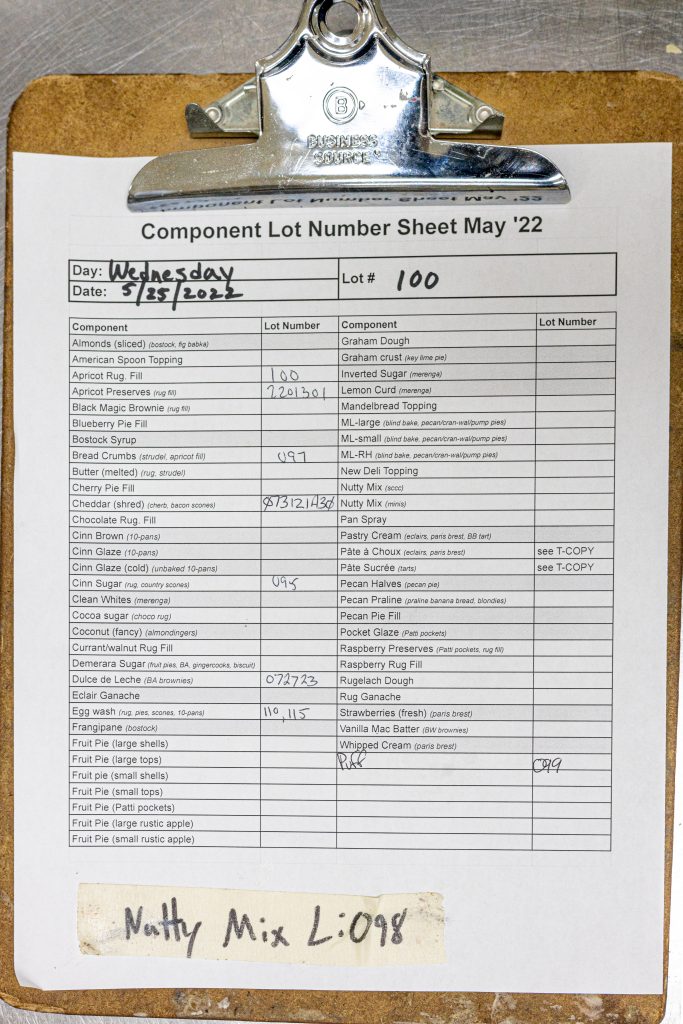

I would say traceability. This means we need to document EVERYTHING! Any time an ingredient is used in a recipe, a component is used to make a product, a label is printed and applied to a baked good, we need to document and track it! And as you can imagine, this happens hundreds, or probably thousands of times a day. We make quite a variety of items with many different ingredients and components.

6. So we know Food Safety is becoming a much larger, more critical thing to manage. What systems are in place to make sure food safety guidelines are being followed?

We have quite a few systems in place. The main ones that cover the entire scope of our work are our Prerequisite Plans. We have 15 of these. A few examples are Supplier Approval, Storage, Employee Training, Cleaning and Sanitation, and Delivery. These are the documents that state what we’re going to do to keep our food safe.

From there we have more detailed Safe Food Practices of how we’re going to do that, like requiring gloves or quick sheets (single-use papers used to grab items when gloves aren’t available) for any Ready-to-Eat food or Hot Holding soup at the correct temperature.

And then even finer detailed SOPs (standard operating procedures) of exactly how those Safe Food Practices work in real time with our exact foods. For instance, step-by-step instructions of how we cool our lemon curd to follow the Safe Food Practice of Cooling TCS Foods (Time/Temperature Control for Safety).

We also do mock inspections quarterly to ensure we’re doing what we say we’re doing, and that we can continue to do it consistently.

7. Speaking of health inspections, how often do they happen and what do they look like? Is there anything we do to prepare for them?

Health inspections come typically about every 1 to 2 years, but there’s generally no warning or telling when they will show up. The inspectors will walk through the entire building with us and observe the work in the bakery. They ask questions about our systems and practices, they often test our sanitizers, and they also audit our documentation and Food Safety Plan.

The way we prepare is through our mock inspections. The idea is to catch any little issues that need to be fixed or any retraining that needs to happen before we have an official inspection.

8. In training for your new position, has there been anything that has surprised you about Food Safety?

As an 80’s baby, just the levels that are necessary to keep food safe. Growing up, I wouldn’t think that heating up a potato would require a full proper cooling procedure to keep it safe. But alas, it does, so we’ll do it!

9. What’s your favorite part about your new role?

I’m a deliberate type-A person, no shame! I enjoy the systems and knowing the ‘why?’ behind them. I feel powerful knowing the information to keep our food safe. And I enjoy teaching others.

10. Anything else you want to share?

Through my time here, I’ve learned so much about managing people and even more about myself. I have truly grown up at the Bakehouse. I have worked here for almost half my life. That’s a bit crazy to think about, but it’s true! I met my fiancé here, and we’ve been together for over 15 years now. I really feel at home here.

Hungry for More?

- Check out our first Behind the Bakes installment on glove-wearing

- Leave a comment and let us know w2hat food safety topic we should cover next

Corynn Coscia is the marketing assistant manager and photographer at Zingerman’s Bakehouse. After spending her childhood reluctantly in front of the camera of her hobbyist-photographer father, she was eager to move behind it, prompting her to pursue a BA in Film & Video Studies at the University of Michigan. With degree in hand, she moved to Los Angeles where she worked in the TV and music industries before discovering her passion for food photography while working in marketing with a plant-based chef. 2 dogs, 2 kids, and 13 years later, she’s back in Ann Arbor doing what she loves and somehow getting paid for it. She recently completed a photography fellowship with her mentor, New York Times food photographer Andrew Scrivani, and has since been shortlisted for a Pink Lady Food Photographer of the Year award. Her photos can be seen throughout the Bakehouse on the walls, on the website and social media, and in the Bakehouse’s series of cookbooklets; she hopes they’re making you hungry!